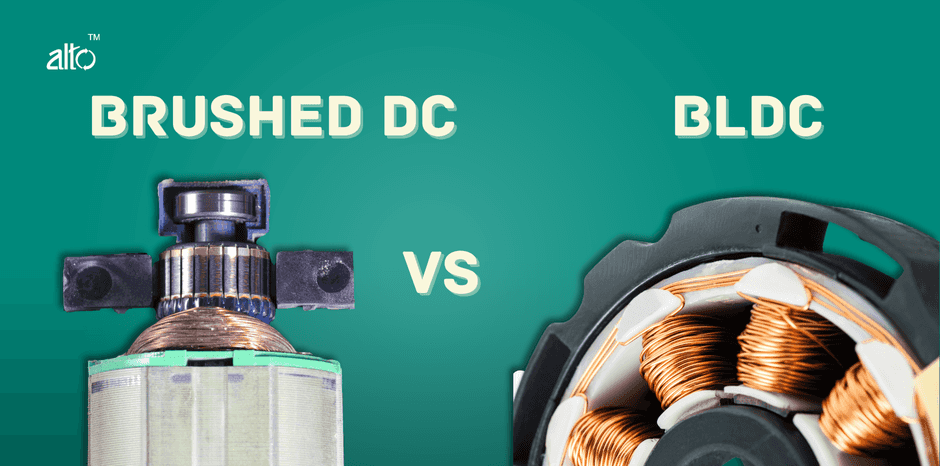

Brushed vs. Brushless DC Motors

An Overview

Sept 19, 23

Keshank Parmar

12 Minutes Read

Introduction

When it comes to electric motors, particularly in applications like electric vehicles, drones, and various consumer electronics, the choice between brushed and brushless DC (direct current) motors becomes crucial. Both types of motors have their unique advantages and limitations, which makes them suitable for specific applications. In this blog, we'll explore the fundamental differences, pros, and cons of brushed and brushless DC motors.

Brushed DC Motors

Basics : A brushed DC motor uses brushes to mechanically switch the current direction in the coils. The brushes run against two or more commutator segments, causing the current to change direction and the motor to rotate.

Advantages

1. Simplicity

Brushed motors are relatively simple in design and construction. This simplicity translates to lower initial cost.

2. Control

They can be easily controlled using simple voltage variation techniques. Increasing or decreasing the voltage can change the speed of the motor.

Disadvantages

1. Wear and Tear:

The brushes in the motor wear out over time, requiring replacement. This wear and tear can cause sparks, leading to reduced efficiency.

2. Maintenance:

Due to the presence of brushes, these motors require more maintenance.

3. Efficiency::

Brushed motors are generally less efficient than brushless motors, especially at higher speeds.

Brushless DC Motors (BLDC)

Basics :Brushless DC motors, as the name suggests, do not use brushes. Instead, they rely on electronic controllers to switch the current direction in the coils. The rotor inside a brushless motor is driven by magnetic forces which arise from the current.

Advantages

1. Longevity :

Since there are no brushes to wear out, brushless motors tend to have a longer lifespan.

2. Efficiency :

They are more efficient, especially at higher speeds, and produce less heat.

3. Maintenance :

With no brushes to replace, brushless motors require less maintenance.

4. Efficiency :

Brushless motors can offer better performance and torque over a wider speed range.

Disadvantages

1. Cost:

They are typically more expensive than brushed motors due to the complexity of the electronic controller.

2. Control Complexity:

The electronic controllers make the control mechanism more complex than a brushed motor.

Which One to Choose?

The choice between brushed and brushless DC motors largely depends on the specific application and requirements:

Budget-Sensitive Projects

If you're working on a budget-sensitive project, a brushed motor might be the better choice due to its lower initial cost.

Long-term applications:

For applications where longevity and reduced maintenance are crucial, a brushless motor is the better option.

Performance-critical projects:

If you need higher performance and efficiency, especially at varying speeds, brushless is the way to go.

Conclusion

In summary, while brushed DC motors have been around for a long time and offer simplicity and easy control, brushless DC motors bring enhanced efficiency, longevity, and performance to the table. As technology continues to evolve, the cost of brushless motors and their controllers is expected to decrease, making them even more prevalent in various applications. When choosing between the two, it's essential to weigh the pros and cons against your specific needs and budget.